Itsuo Doi Shirogami #3 Sakimaru Takohiki - Migaki 300mm

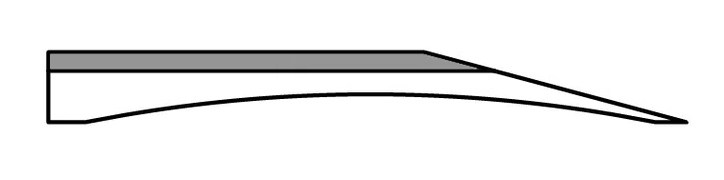

This knife, reflecting Japanese sashimi tradition, is designed for professional use; its long, straight takohiki form, characteristic of the Kanto style, combined with a katana-like sakimaru tip, offers both aesthetics and superior control. The high-purity Shirogami #3 carbon steel provides an exceptionally fine and smooth sharpness while offering easy sharpening; the migaki (polished) surface gives it a simple and elegant look. Its single-bevel geometry allows for clean slices in a single stroke without damaging raw fish fibers, and its 300mm length is ideal for masters who seek maximum fluidity and precision, especially in sashimi and sushi preparation.

Products Purchased Together

Technical Specifications

Blade Type: Takohiki

Steel Type: Shirogami #3 (Beyaz Çelik #3)

Geometry:

Lamination:

Surface Treatment:

Hardness (HRC): 62

Total Length:

Blade Length:

Blade Width:

Spine Thickness:

Weight:

Stem Length:

Handle Color:

Handle Material:

Kanji on the knife:

Manufacturer:

Location of Origin: Sakai, Osaka, Japan

Knife Care and Use

Delivery and Returns

Free Shipping: All orders are shipped free of charge via Yurtiçi Kargo or MNG Kargo.

30-Day Return Policy: You can return your order within 30 days of receiving it.

Refunds: Refunds for returned items will be processed and transferred to your bank within 3 business days. The refund amount will typically appear on credit cards within 1-3 business days, while this process may take longer for debit cards depending on your bank. Refunds for installment payments will be processed in installments due to bank procedures. You can track the refund process by contacting your bank.

Itsuo Doi Shirogami #3 Sakimaru Takohiki - Migaki 300mm

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ's

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Finish your knife

A knife sheath and sharpening steel together to protect your knife and keep it ready at all times.

MAC Ceramic Sharpening Steel - 1200 Grit

Are you having trouble making a decision?

Choosing the right knife for the kitchen can be tough! Take our quick quiz and discover the perfect Japanese chef's knife for you.

Follow us

Follow us on Instagram to stay updated on our new products.

FAQ

For more information, please visit our Frequently Asked Questions page.

Why are Japanese chef's knives so sharp?

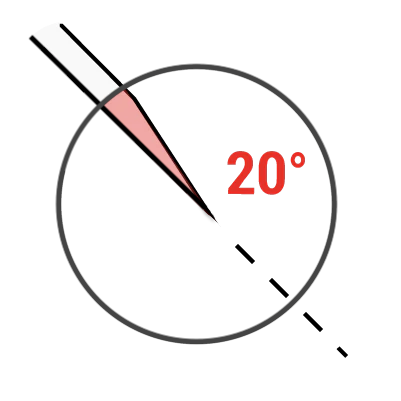

The main reason Japanese knives are sharper is due to the angles of the blades and the steel technology used. High-carbon Japanese steels offer a harder structure and remain sharp for longer. These steels generally reach hardness levels above 60 HRC and are sharpened at narrow angles such as 15°. However, since brittleness can increase with hardness, proper use and regular maintenance are important.

How should I maintain carbon steel blades?

Knives made from carbon steel are susceptible to rust. Therefore:

- It should be thoroughly dried after each use.

- It should be regularly lubricated with a thin layer of maintenance oil.

- It is not recommended to wash any chef's knife in the dishwasher.

With proper care, your knives will maintain both their performance and their aesthetic appearance for a long time.

Which knife should I choose?

Choosing the right knife for your kitchen depends on your cooking habits and cutting style. The right knife can make your cutting experience more efficient and enjoyable. But don't worry if you're unsure which knife is right for you!

Take our short quiz to find the perfect knife for you and discover the chef's knife that best suits your needs.

Start the test

What is the difference between quality knives and mass-produced knives? How can I tell the difference between quality and quality?

It's not accurate to classify the quality of a knife solely by whether it's "handmade or mass-produced." High-quality models can be found among both handcrafted and mass-produced knives.

The key factors here are:

- The quality of the steel used.

- Workmanship level

- Attention to design details

Mass-produced knives are manufactured quickly and in large quantities using modern machinery. Their affordability and advantages such as stainless steel make them attractive for everyday use. However, not all mass-produced knives are created equal; some brands produce to high standards, while others focus solely on aesthetics.

High-quality knives , whether handmade or machine-made, should meet the following criteria:

- Use of high carbon or special alloy steel

- Ideal edge angle and homogeneous sharpening in terms of precision.

- Well-balanced handle and ergonomic grip.

- Precision in workmanship and robust construction.

Models produced using traditional methods, such as Japanese knives, stand out particularly for their sharpness, precision, and aesthetics. However, they may require special care.

In conclusion, the key to understanding a quality knife lies less in its production method and more in evaluating the expertise, material selection, and craftsmanship behind the product.

Every knife featured on iyibicak.com is meticulously selected according to these standards.

From which countries do you sell knives?

We offer knives from many countries renowned for their craftsmanship, primarily Türkiye and Japan. Our aim is to bring the best production traditions and knife-making skills from each culture into kitchens.

What is the difference between European steels and Japanese steels?

Japanese steels (e.g., VG-10, SG2, Aogami) are exceptionally hard due to their high carbon content. This hardness allows for sharpening blades with finer edges and provides razor-sharp performance. They typically have hardness ratings of 60 HRC and above and can remain sharp for a long time. However, this high hardness can also lead to a more brittle structure. Therefore, they require careful handling and regular maintenance.

European steels (e.g., German X50CrMoV15 or French T12) have a softer and more flexible structure. They generally have a hardness range of 56–58 HRC. This makes them more impact-resistant, easier to sharpen, and more comfortable for everyday use. They also have a high corrosion resistance.

In conclusion :

Japanese steel is ideal for those seeking sharpness and performance.

European steel is more suitable for users who prioritize durability and ease of maintenance.

We recommend you make your choice based on your frequency of use and expectations.

What are the return conditions?

At İyi Bıçak, we prioritize customer satisfaction. If for any reason you are not satisfied with your purchase, you can return it within 30 days , provided it is unused and in its original packaging. After creating your return request, you must securely package the knife and send it to us. Once we receive the product, we will conduct the necessary checks, approve your return, and refund your payment to your account shortly.

To prevent product damage and maintain hygiene standards, sharpened knives are not eligible for return . In case of a manufacturing defect or damage during shipping, we can repair or replace your knife and send it back to you. If you have any questions about the return process, please feel free to contact us.

Information

Aogami Çelik Serisi Nedir? Aogami #2, #1 ve Super Arasındaki Farklar

How to Store Carbon Blades: The Secret to Perfect Sharpness and Long-Lasting Use

Japanese Fishing Knives: A Guide to Usuba, Yanagiba, and Deba Knives

![Naniwa Sharpening Stone - #3000 [Super Stone Series]](http://iyibicak.com/cdn/shop/files/Naniwa_Sharpening_Stone_-_3000.webp?v=1743694733&width=5000)

![Naniwa Sharpening Stone - #12000 [S1 Super Stone Series]](http://iyibicak.com/cdn/shop/files/Naniwa_Sharpening_Stone_-_12000_SP-491.webp?v=1743695225&width=5000)

![Naniwa Sharpening Stone - #2000 [Super Stone Series]](http://iyibicak.com/cdn/shop/files/Naniwa_Sharpening_Stone_-_2000_S-420_07043300869.webp?v=1743694854&width=2000)

![Naniwa Sharpening Stone - #8000 [Super Stone Series]](http://iyibicak.com/cdn/shop/files/Naniwa_Sharpening_Stone_-_8000_SS.webp?v=1743694486&width=3000)

![Naniwa Sharpening Stone - #12000 [S2 Super Stone Series]](http://iyibicak.com/cdn/shop/files/SuperStone12000_070441001061_2_30ad4922-5534-478a-8d7a-0ba16b9d6eb9.webp?v=1743693963&width=3000)

![Naniwa Double-Sided Sharpening Stone - #1000 #3000 [Super Stone Series]](http://iyibicak.com/cdn/shop/files/NaniwaCombinationStone10003000_070438001060.webp?v=1743692402&width=3000)

![Naniwa Sharpening Stone - #1000 [Super Stone Series]](http://iyibicak.com/cdn/shop/files/Naniwa_Sharpening_Stone_1000.webp?v=1743692776&width=5000)

![Naniwa Sharpening Stone - #400 [Super Stone Series]](http://iyibicak.com/cdn/shop/files/Naniwa_Sharpening_Stone_-_400.webp?v=1743692553&width=5000)

![Naniwa Sharpening Stone - #800 [Super Stone Series]](http://iyibicak.com/cdn/shop/files/Naniwa_Sharpening_Stone_-_800_S-408_07044100210.webp?v=1743693797&width=2000)

![Naniwa Double-Sided Sharpening Stone - #400/#2000 [Super Stone Series]](http://iyibicak.com/cdn/shop/files/NaniwaCombinationStone4002000_070438001059.webp?v=1743693499&width=3000)