Lamination Techniques

San Mai

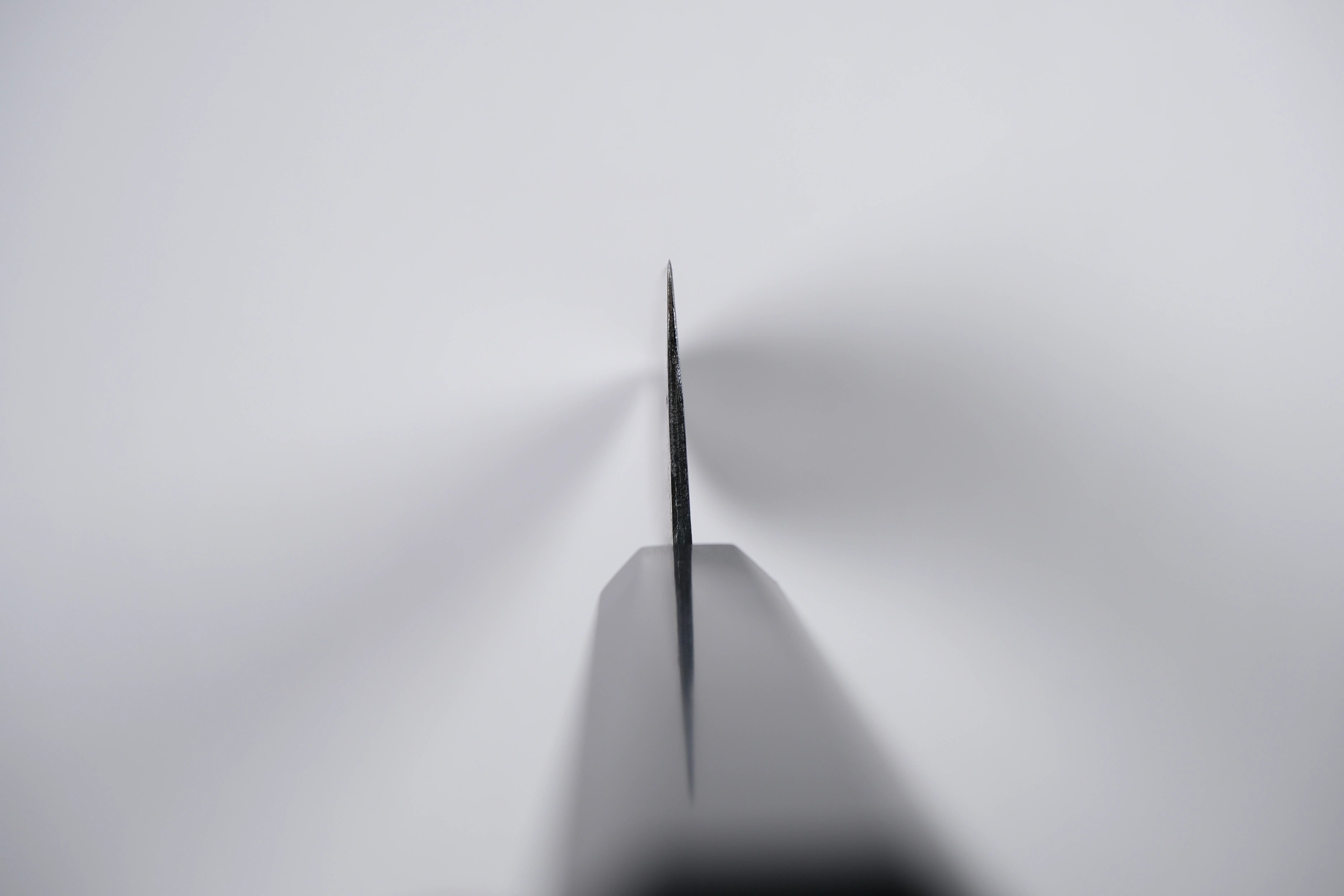

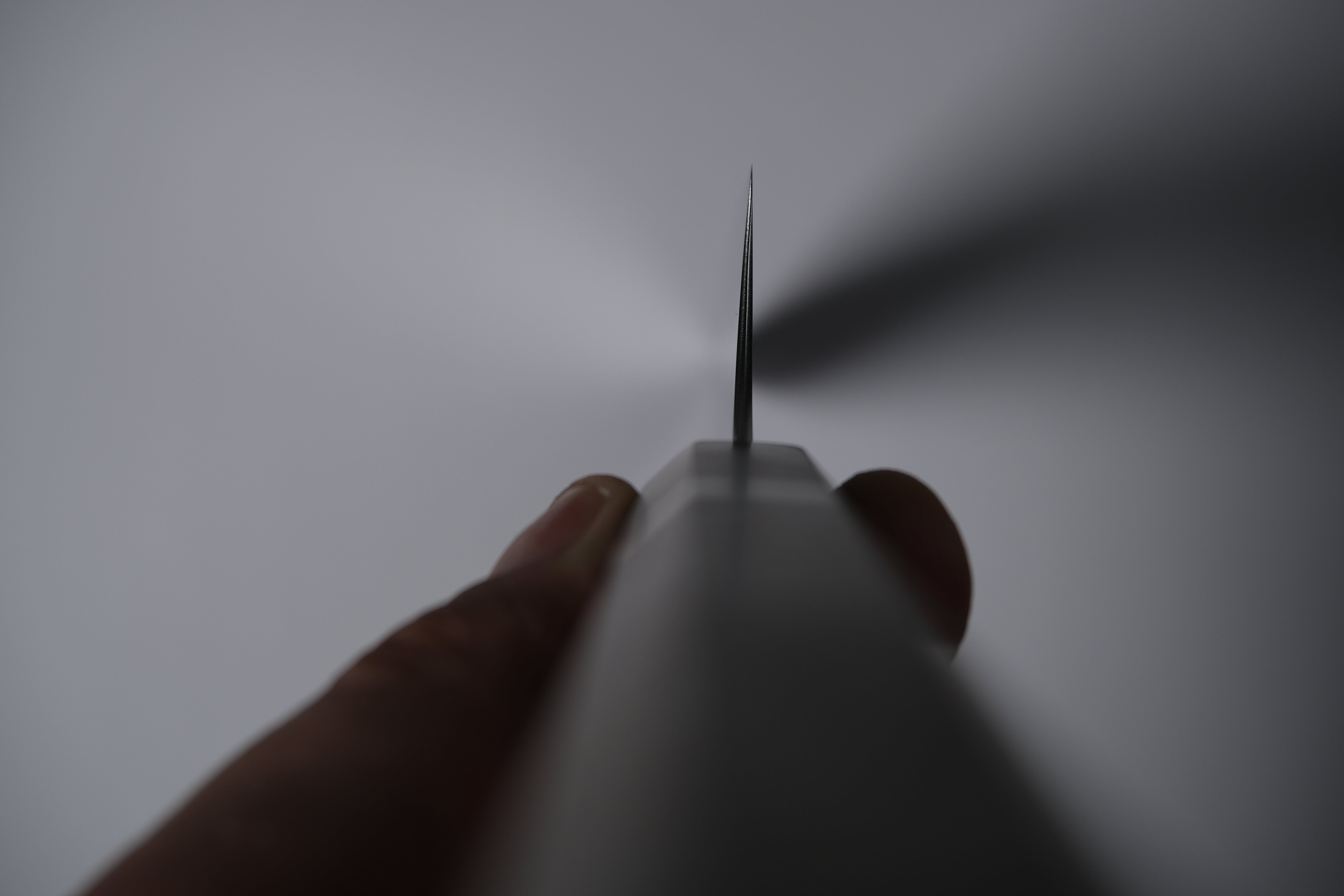

San Mai (三枚) means "three layers" in Japanese, and this lamination method involves using a hard steel core in the blade while coating the outer layers with softer, more flexible steel. This method is one of the most popular Japanese knife-making techniques, combining sharpness and durability.

Core Steel (Hagane): This is the central layer that forms the cutting edge of the blade. High-carbon steels such as Shirogami (White Steel), Aogami (Blue Steel), or stainless steel types are typically used. This layer provides superior sharpness and hardness.

Outer Layers (Jigane): A softer steel or stainless steel is used. These layers make the blade more resistant to impacts and reduce brittleness. They can also help make the blade more resistant to rust.

These three layers are fused together by forging at high temperatures, and then brought to their final form through traditional forging, grinding, and polishing processes.

San-Mai Collection

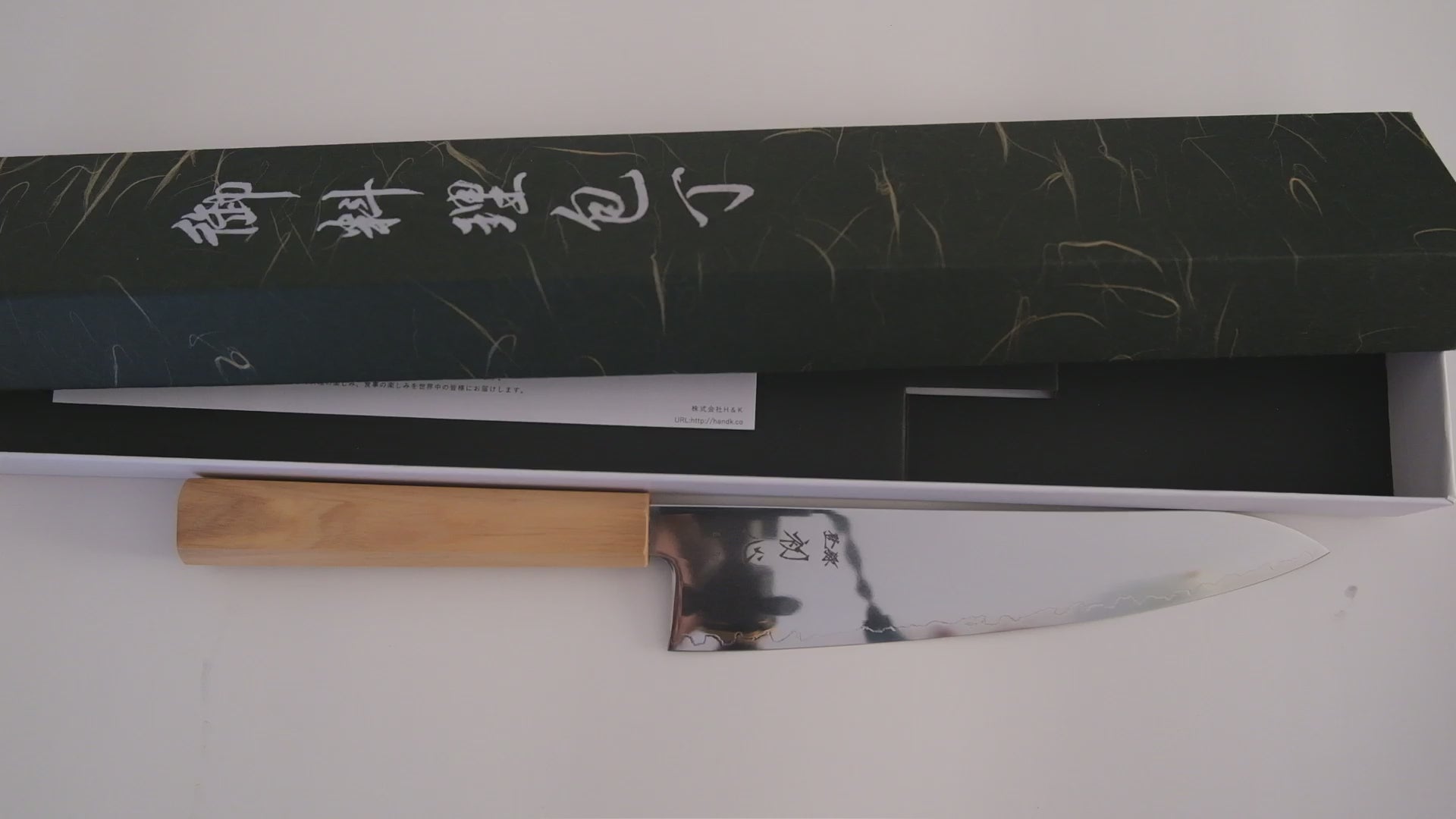

Tsunehisa Shirogami #2 Kiritsuke - Tsuchime 210mm

Hatsukokoro Hikari SLD Kiritsuke Petty - Mirror 125mm

Hatsukokoro Hikari SLD Gyuto - Mirror 195mm - Olive Wood

Damascus

Damascus steel is a special manufacturing method that maximizes both functionality and aesthetic value in knife production. In this technique, the hard steel core that forms the cutting edge of the blade is placed between softer and more flexible outer layers. Unlike the classic San-Mai lamination, this method uses five or more (always an odd number) layers of steel. This is why it is sometimes called Suminagashi. Suminagashi, meaning "ink flow" in Japanese, refers to a pattern similar to traditional marbling art, and this name is used because the wavy patterns seen on the surface of Damascus steel resemble this art.

Damascus Collection

Damascus steel is created by layering different metal alloys on top of each other and then forging them into a single piece. In this process, the high-carbon, hard core steel ensures the blade remains sharp for a long time, while the outer layers provide flexibility and reduce brittleness. The combination of different metals, such as stainless steel or nickel-based alloys, reveals the unique patterns of Damascus steel. Craftsmen repeatedly forge the steel, heated to high temperatures, shaping it to achieve a harmonious blend of different metals and accentuate the aesthetic patterns. In the final stage, the blade is treated with acidic solutions or special surface treatment techniques to make the patterns even more visible.

The most striking feature of San-Mai Damascus steel is its unique visual appeal and the distinctive patterns created through handcrafted workmanship. Technically, a knife might only require two outer layers of hard core steel. However, the multi-layered structure of Damascus steel adds both aesthetic value and allows the craftsman to showcase their skill. Therefore, San-Mai Damascus knives are considered more than just a kitchen tool; they are also seen as works of art and collector's items.

Tsunehisa Ginsan Santoku - Nawame Damascus 165mm

Tsunehisa VG-10 Gyuto - Damascus Tsuchime 180mm

Hatsukokoro Hikari SLD Santoku - Damascus 170mm

Suncraft VG-10 Bunka - Black Damascus 200mm

Suncraft VG-10 Bunka - Damascus 165mm

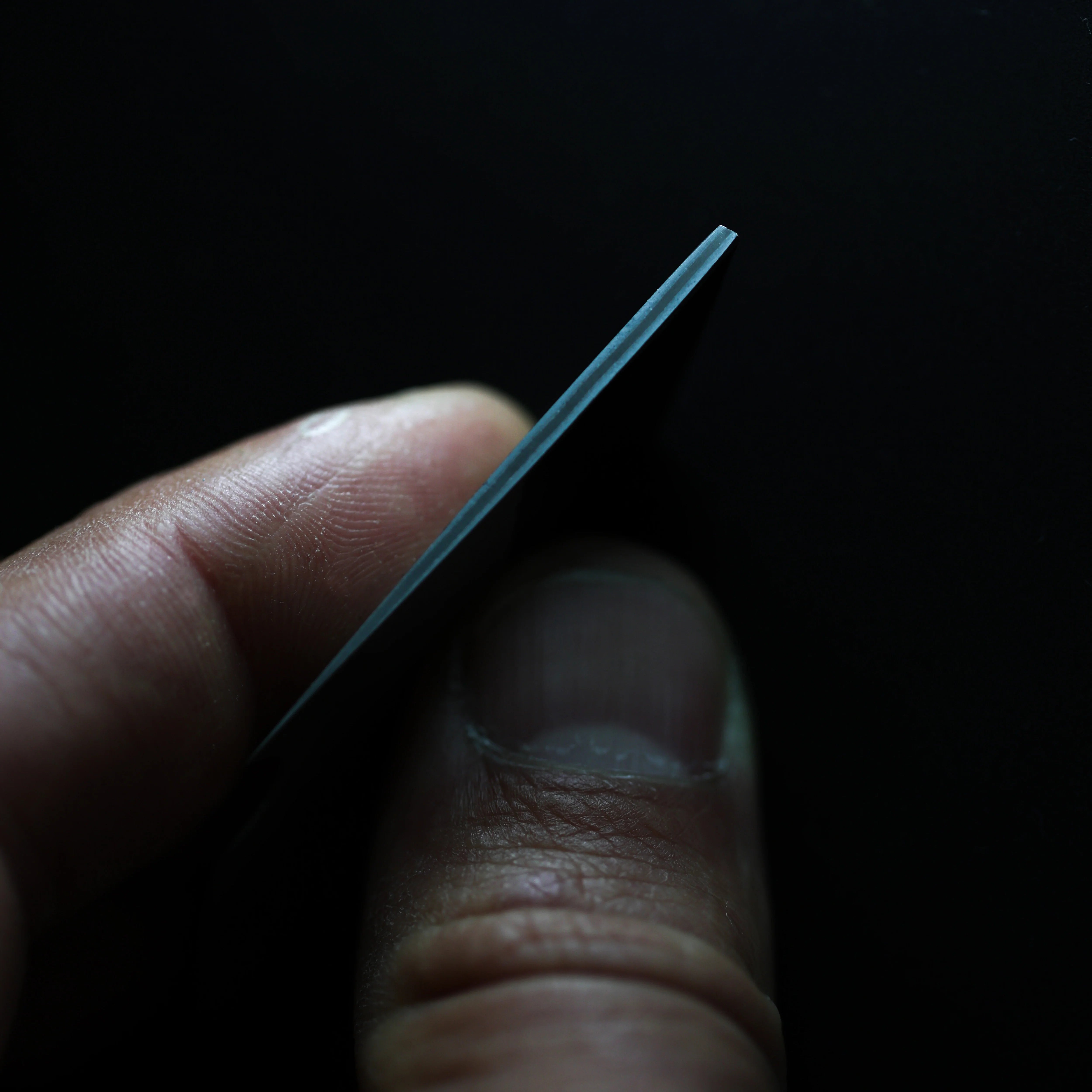

Monosteel

Monosteel knives are made from a single, high-hardness steel without any lamination. Thanks to this special manufacturing method, they have no patterns on their surface and generally have a mirror-polished finish. Distinguished by their minimalist design, these knives combine sharpness, durability, and elegant aesthetics.

Monosteel Collection

One of the biggest advantages of Japanese monosteel knives is that they stay sharp for a long time thanks to being made using high-carbon steels. Steel types such as Shirogami (White Steel) and Aogami (Blue Steel) are particularly known for their superior sharpness and precise sharpening capabilities. Stainless steel versions use materials like VG10 or SG2, which reduces the need for maintenance.

These types of knives are highly resistant to scratches and, thanks to their homogeneous structure, prevent unwanted deformations from occurring on the blade edge.

Tsunehisa SLD Santoku - Migaki 180mm

Tsunehisa AUS-8 Yanagiba - 270mm

Tsunehisa AUS-8 Yanagiba - 240mm

Tsunehisa AUS-8 Ko-Deba - 120mm

Tsunehisa AUS-8 Yanagiba - 300mm

Ni-Mai

While Ni-Mai lamination is similar to San Mai and Warikomi techniques, its main difference is that a layer of soft steel is present on only one side of the blade (usually the back surface). This structure is created in the following way.

Ni-Mai Collection

Core Steel (Hagane) - Cutting Edge:

It is made from high-carbon hard steel. Shirogami (White Steel) or Aogami (Blue Steel) is commonly used. It has an ideal structure for superior sharpness and precise cuts.

Outer Layer (Jigane) - Back Section:

A softer steel or stainless steel is used. This reduces the brittleness of the blade, making it more durable. It improves stability and cutting control in single-edged blades.

In this design, the cutting edge is made entirely of hard core steel, with only the back of the blade covered in mild steel. This ensures excellent sharpness and stability.

Hokiyama Hamono AUS-8 Yanagiba - 240mm

honyaki

In the production of Honyaki knives, the steel is subjected to special heat treatments and then repeatedly forged to form the blade shape. This process ensures an even distribution of carbon and chromium molecules within the steel. A special clay coating is then applied to the back of the blade, and the blade is cooled at different rates. This process is the same differential hardening technique used in Japanese sword making.

This special heating and cooling process results in a very hard cutting edge on the blade, while the spine remains slightly softer and more flexible. Thanks to these different hardness levels, the blade stays sharp for a long time and is also resistant to impacts.

This process results in a wavy pattern on the blade's surface called "Hamon." The Hamon is a hardness gradient formed by the varying cooling rates during the heating and quenching process of the blade, and it is unique to each Honyaki knife. Some knife makers use special grinding and polishing techniques to make this pattern more pronounced. The Hamon pattern not only enhances the aesthetic beauty of the blade but also serves as an important indicator that the blade has undergone the traditional manufacturing process.

Honyaki knives are considered masterfully crafted works of art and represent the pinnacle of traditional Japanese knife making. Owning a Honyaki knife is not just acquiring a kitchen tool, but also bringing a craft and heritage into your kitchen.

Warikomi

Warikomi (割り込み) is a traditional lamination method used in Japanese knife making, and its name literally means "inserted" or "gripped core." In this technique, a hard and sharp core steel (hagane) is coated on both sides with softer steel. While similar to the San Mai method, Warikomi utilizes a more two-layered structure.